WWS SLUDGE REDUCTION – ALCOSAN – PITTSBURGH, PA, USA

180 MGD / 681,000 m3/Day

- Bacterial strains used to produce ACF-AD On-Site Products have been selected and cultivated to increase the hydrolytic enzyme capacity of a typical conventional activated sludge plant by up to 50%

- Utilized two 2,500 Gallon On-Site BioReactors, aerating 50 LBs of ACF-AD for 48 Hours in non-chlorinated water, applying half of the tank at 36 Hours and balance at 48, with two tanks the application was staggered for daily dosing

to the system - Accompanying increase in solubilization rate can cause reduction in waste activated sludge yields of 25% or more

- ALCOSAN System serves Pittsburgh and surrounding suburbs, population: 1,700,000

- Average daily flow is 180 million gallons or about 681,000 m3 per day

- Trial period showed reductions in Sludge Generation of over 60%, representing a net savings of about $1,000,000 per year

WWS SLUDGE REDUCTION – REDWOOD FALLS, MN, USA

Sludge and Ammonia Reduction

Pond Configuration: Three x 10 million gallon aerated ponds, in series, each 10 feet deep, treating 0.8 MGD (800,000 gallons per day) of municipal waste water.

Challenge: The treatment facility had ongoing algal bloom and sludge build up problems, particularly in the first of the three ponds. Due to sludge build up, the ponds required expensive dredging (the pond were dredged every few years prior to use of BP products). Along with the sludge build up, odor problems and high effluent Suspended Solids ensued.

Treatment: A 175 gallon On-Site Bioreactor was used, where ACF-AD was aerated for 48 hours, ACF-32 was added during the last 4 hours, and then the product was applied to the system. To enhance the sludge removal performance, ACF-BacBags were used in the first pond to provide 30 day continuous release of enhanced enzymes.

Results: Due to product use, all object were achieved: Effluent Suspended Solids have been within NPDES permit limitations. Algae and Odor problems were solved. Over a 50% reduction of TSS, Sludge and Phosphorous was achieved. Whereas sludge dredging had been required every few years prior to BP product use in 2001, no dredging has been necessary for over ten years. Eliminating the need for dredging for over a decade has saved city authorities a tremendous amount of money, and has been the most significant benefit achieved through our program.

WWS DEGRADE COD AND BOD – ROUSINOV WWS – CZECH REPUBLIC

Carousel system continued treatment.

- System designed to create aerobic zone for BOD Removal and Nitrification, flowing to anoxic zone for denitrification

- ACF-AD and ACF-SC improved reduction of BOD and COD by 69%, and improved the removal efficiency of total nitrogen pollution by over 60%

- Decreased sludge from an average of 240 ml/g to 125, improved settling properties by 65% and reduced organics in stabilized sludge

WWS EMERGENCY RECOVERY AND PRE-TREATMENT METHOD

- Pre-treat utilizing the existing sewage collection pipes, applying on-site brewing of ACF-AD and ACF-SC to the headwaters can significantly reduce COD, BOD and Odors; improving overall performance w/o capital expenditures

- Used as an emergency method when waste water needs to be diverted due to heavy rain/hydraulic blowouts

- Can reduce COD by over 65% within 1000 feet of a collection and/or discharge pipe-line system

- Faster restarts of activated-sludge systems, can be done within days, not weeks

IMPROVED NITRIFICATION IN WWS – SALISBURY, MA, USA

AMMONIA LOWERED BY OVER 200%

- System Failures due to Hydraulic Blow-Outs and/or Bio-Collapse, Inefficient Nitrification of Ammonia

- Results after two applications of On-Site Bioreactor Product

- Restarted activated-sludge systems within days, not weeks

SEPTIC AND GREASE TRAP – 120 UNIT APT BUILDING – MEXICO CITY

ODOR PROBLEM SOLVED IN LESS THAN 2 WEEKS

“Complaints from residents have completely disappeared. It is even more impressive to me that the odor reduction occurred in summer, when we normally have our most severe odors and highest incidence of complaints.” – Administrator

- Wastewater from this complex serviced by an OSSF consisting of equalization, activated sludge, secondary clarifiers, and chlorination

- Final effluent is used for irrigation

- The OSSF is designed for 150,000 liters per day flow

- Prior to ACF-BacBags use beginning on May 27, 2013, the OSSF System was the cause of frequent and persistent sulfide odors that could be smelled up to the 20th floor of the facility

- Irrigation water tanks were also serious source of odor complaints

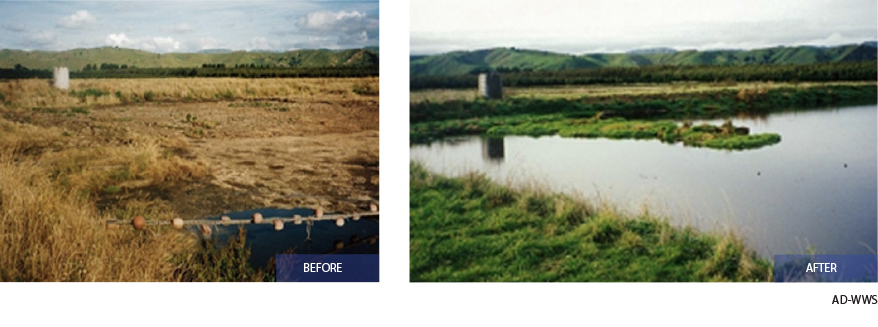

RESTORED SYSTEM BALANCE – CHEESE PROCESSING PLANT

SOUTH AFRICA

- Odors eliminated

- Treatment of DAF System (FOGS / WHEY)

- 5km Pipeline cleaned of FOGS (fats, oil, greases)

- Oxidation dams rehabilitated

- Sludge lifted and hydrolysed

- Whey spills controlled in dam

- Discharge Pastures restored

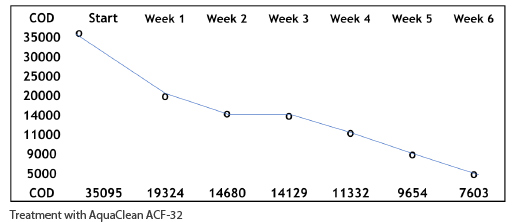

RESTORED SYSTEM BALANCE – WINERY

SOUTH AFRICA

- Waste Water had extremely high COD, and complaints on Odor were wide spread

- After six week of treatment with ACF-32 the COD had been reduced by 94%

- Odor was eliminated after only 10 Days

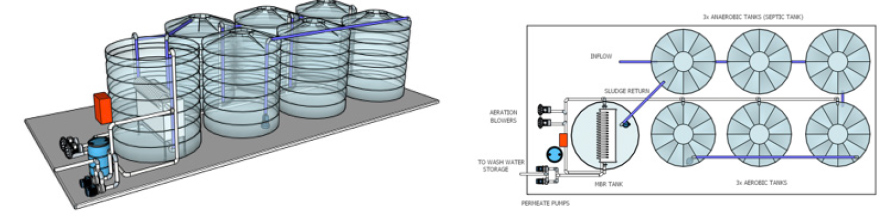

ABATTOIR WWS DESIGN / BIO-EFFECTIVE METHODOLOGY

WWS Dual Design Separates Load Flow to address the practical and bio-chemical requirements for effectively degrading Abattoir Waste. System Failures are due to an imbalanced load that provides bacteria easy to degrade blood waste along with more difficult to grade waste.

- Abattoir Systems separates the solids from blood flow

- Solids with Fats, Oil and Grease are treated first in anaerobic, then aerobic retention tanks, and finally filtered by MBR…producing recycled water for facility washing and irrigation use…which may be further treated by R/O for a

potable water source - Blood Flow is diverted into separate Anaerobic Tanks, treated and then released to oxidation lagoons for polishing

SLAUGHTER HOUSE – MEMBRANE BIOREACTOR – DISCHARGE LAGOON

SOUTH AFRICA

- Sludge Hydrolyses too slow, causing: Bottom Sludge Build Up, Reduction in Retention Time, Surface Crust, Odor, Flies / Mosquitos, Expensive mechanical de-sludging

- Reduction of 663.5 m³ of total dry solids in first 12 months.

- Equates to 4,644 tons of non-centrifuged wet solids.

- Approximately 309 truck and trailer loads were removed.

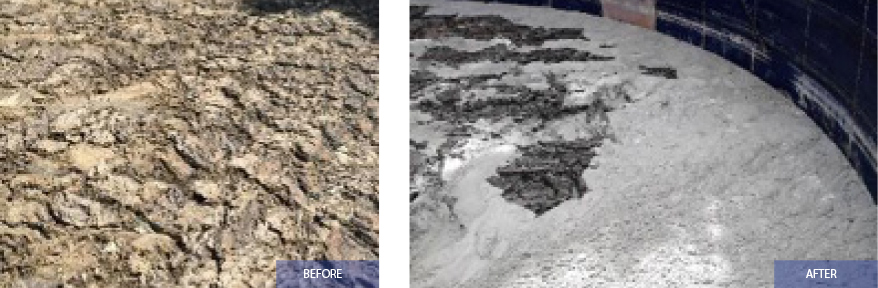

ABP WATERFORD – SOUTH AFRICA

BIOLOGICAL BALANCE RESTORED

ODOR ELIMINATED

- Balance Tank – 30 m

- Mix of Abattoir and Rendering Waste

- Huge odor issues

- 1 m Crust

- Needed to remove crust in order to empty tank and cover it

- Must complete in 4 weeks or face fines

- Within 2 ½ weeks the odor was eliminated and the mixers were freed

- 30 m³ (1m) Crust hydrolysed

- Settled Sludge hydrolysed

- Biological Balance restored